Reducing Operational Costs with Automated Storage and Retrieval Systems (AS/RS)

Reducing Operational Costs with Automated Storage and Retrieval Systems (AS/RS)

By Diamond Phoenix

// 24 Oct 2024

Are you looking to reduce your operational costs at your warehouse and enhance overall operations?

If so, you've certainly come to the right place. Automated Storage and Retrieval Systems (AS/RS) are revolutionising industry and have proven to be a game-changer for warehouses and distribution centres over the last decade.

Automated Storage and Retrieval Systems (AS/RS) are hugely beneficial in streamlining operations whilst also offering significant cost savings for businesses.

In this latest blog post, we explore the key reasons that these modern-day systems reduce operational costs and why you may want to consider implementation.

Key reasons that Automated Storage and Retrieval Systems (AS/RS) reduce operational costs include:

- Reduced labour costs

- Increased storage density

- Improved accuracy & reduced errors

- Enhanced productivity

- Reduced damage to goods

If you require a site visit or would like to find out more about automated storage and retrieval systems, please call us directly at 01908 592 354 or through our online contact form.

What are Automated Storage and Retrieval Systems (AS/RS)?

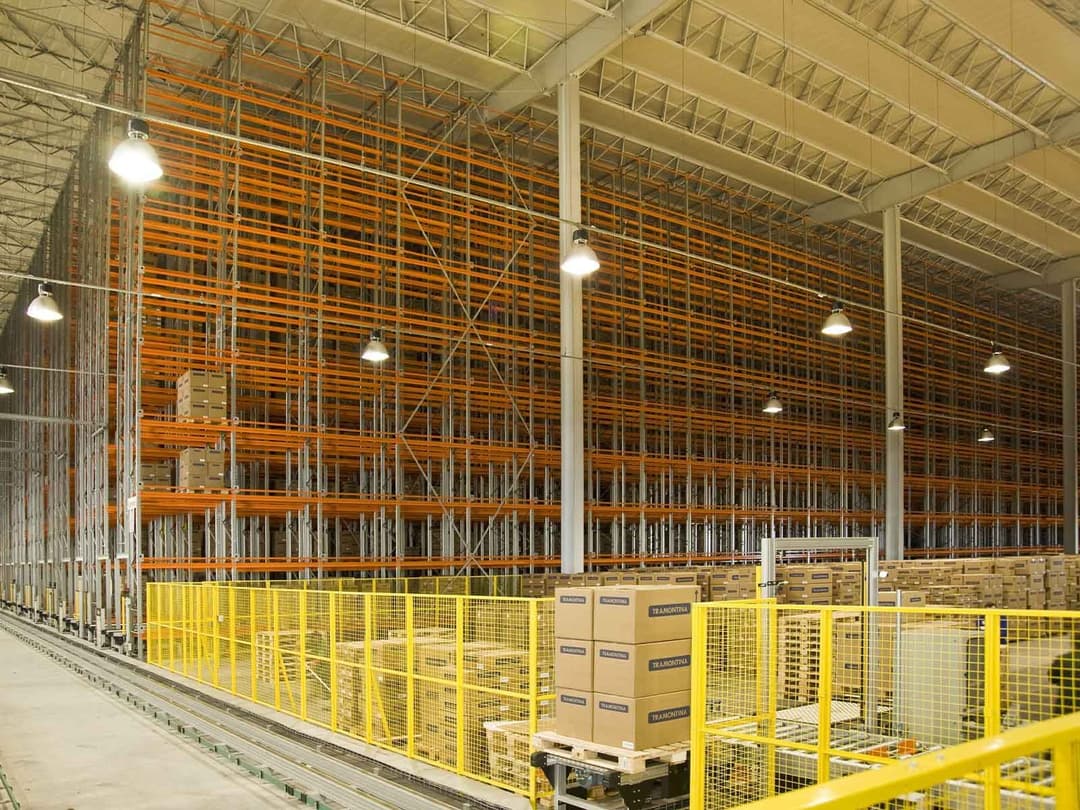

Automated Storage and Retrieval Systems (AS/RS), as the names suggest, are computer-controlled systems used to store and retrieve products in your distribution centre or warehouse.

Essentially, these automated systems minimise and / or eliminate the requirement for manual labour. Moreover, these systems also significantly enhance the speed and accuracy of retrieval and storage.

AS/RS are available in a number of different forms including carousels, shuttle-based systems, unit-load systems, and mini-load systems. As the demand for efficiency and cost reduction continues to rise, investing in automation becomes a strategic advantage that can lead to long-term success, and AS/RS can play an integral part in that.

Let's go into further detail as to how these systems reduce overall operational costs...

Reduced labour costs

Automated Storage and Retrieval Systems (AS/RS) assist in significantly reducing labour cost which contributes to overall lower operational costs on a month-to-month basis. These systems are automated and can perform storage and retrieval tasks that would otherwise be conducted by manual labour. It's recommended that even when implemented, a certain number of employees should still be in place to oversee and maintain processes.

However, this number will be significantly less than before the implementation of these systems, therefore reducing overall labour costs without compromising on speed or accuracy.

Increased storage density

You can also reduce operational costs with Automated Storage and Retrieval Systems (AS/RS) by increasing storage density and therefore benefiting from maximising overall space utilisation. It's not uncommon for warehouses to struggle with limited space and inefficient layouts.

However, with the assistance of these automated retrieval and storage systems, you can optimise storage density with systems having the capability to operate in narrower aisles and make better use of vertical space.

Improved accuracy & reduced errors

Say goodbye to manual storage and retrieval processes, and say hello to improved accuracy and reduced errors. This is another proven way that you'll reduce overall operation costs. Much fewer errors equals less costs associated with correcting mistakes.

The automated technology ensures that products are stored in the correct locations and retrieved accurately when needed. This minimises the risk of errors and improves overall operational efficiency. Fewer mistakes mean fewer returns, lower shipping costs, and enhanced customer satisfaction, all contributing to cost savings.

Enhanced productivity

If you're seeking to speed up your storage retrieval processes, these systems are an excellent choice. Manual processes can often take time as employees or personnel have to walk long distances or operate forklifts within traditional warehouses. Thankfully, there's another way of doing things in modern-day warehousing that reduces your overall operational costs.

Implemented automated systems at your warehouses are centred around moving products quickly and efficiently with minimal delay. Therefore, you can put more orders through in less time, leading to increased revenue without the need for additional labour.

Reduced damage to goods

Manual handling of products can result in accidental damage. As a result of this, it can tarnish business reputation and lead to financial losses that directly impact your profits.

Fortunately, AS/RS systems handle products with care and precision, significantly reducing the risk of damage.

The reduced damage not only saves money but also ensures that customers receive high-quality products, and that your business standardised handling processes.

Contact Diamond Phoenix

The integration of Automated Storage and Retrieval Systems (AS/RS) is expected to continue to surge in the UK and Europe, and for good reason too.

By successfully integrating various systems, you can expect to significantly reduce overall operational costs, enhance accuracy, and reduce damage to goods.

For more information, please call us today at 01908 592 354 or use our convenient online contact form.