Success Story – DFV, Italy

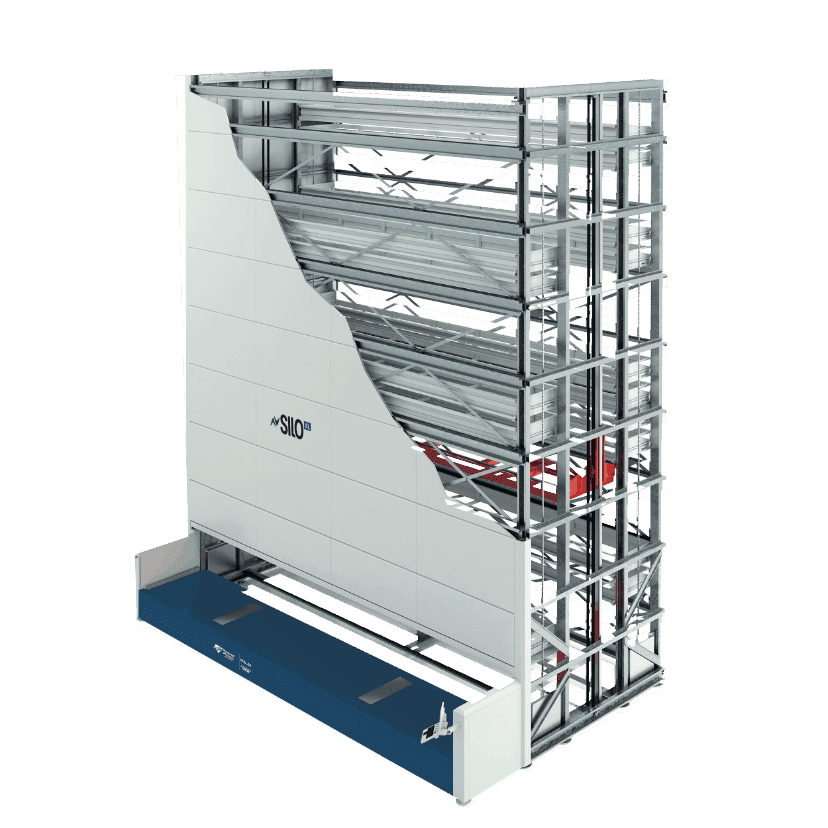

The SILO range from ICAM offers automated, space-efficient and secure storage and retrieval

By Diamond Phoenix

// 23 Mar 2020

In order to tackle their critical issues, DFV decided to install 2 tri-columns SILO² VLMs, near the coating stations with the aim of eliminating time wasted in moving and searching items.

With the aim of avoiding any type of picking errors, both access openings were equipped with an innovative Smart Vision system, entirely developed by ICAM: sophisticated Image Processing algorithms and the reading of QR code on the top of each pack, ensure that the handled packs are correctly positioned, stored and retrieved, highlighting possible anomalies.

The Smart Vision system is connected with ICON, ICAM warehouse management software interfaced with the ERP: each item entering or leaving SILO² vertical lift module is tracked in real-time. The integration of an electronic scale ensure that the stock situation is kept under control and updated regularly to avoid any possible stockout.

The SILO range from ICAM offers automated, space-efficient and secure storage and retrieval

More info on the SILO² range:

Visit the ICAM Silo Product range page

Download the Silo product sheets:

Silo-Plus

Silo-2

Silo-XL

Diamond Phoenix Automation is one of the market leaders in the design, integration and installation of innovative material handling systems such as carton and pallet conveyors, crane stores and picking solutions.