Conveyors Systems In Distribution

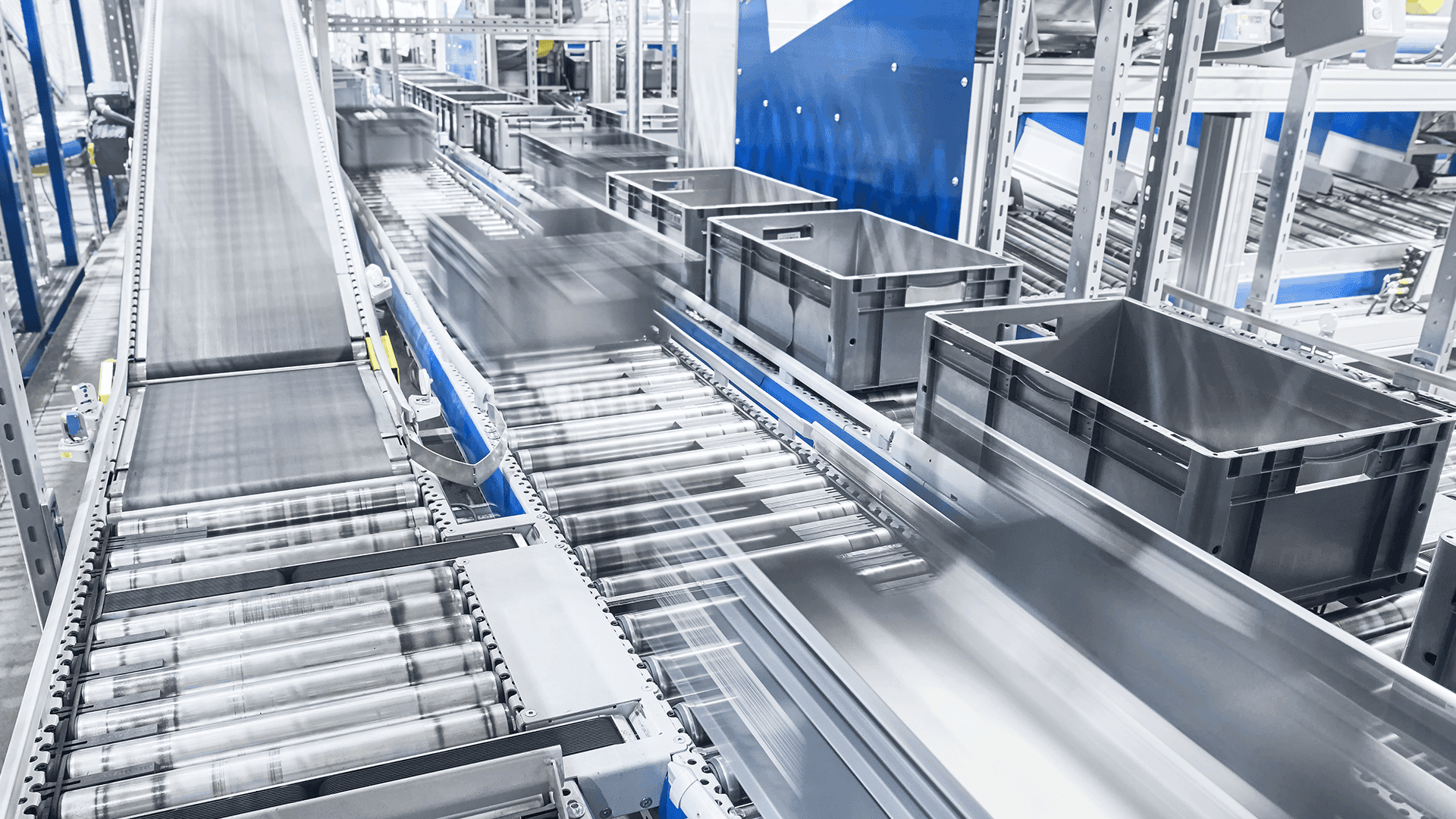

In the dynamic landscape of modern distribution, where speed, accuracy, and scalability are paramount, conveyor systems have emerged as the backbone of streamlined operations.

By Jake Powell

// 4 Jan 2024

From e-commerce giants managing a vast array of products to traditional distribution centres optimising supply chain processes, the utilisation of conveyor systems has become a pivotal element in enhancing overall efficiency.

In this blog, we’ll explore the multiple benefits of conveyor systems in distribution and how they contribute to the success of businesses in a rapidly evolving market.

Key benefits will cover the following;-

- Streamlining order fulfilment

- Handling diverse products with versatility

- Maximising space utilisation

- Enhancing sorting and routing efficiency

- Embracing technology for smarter operations

- Promoting workplace safety

If you’re looking to discuss your bespoke requirements for conveyor systems right away, you can call us today at 01908 592 354 or use our online contact form.

Streamlining Order Fulfilment

One of the primary challenges in distribution centres is the need for quick and accurate order fulfilment. Conveyor systems play a pivotal role in addressing this challenge by automating the movement of products throughout the facility.

As orders are received, conveyor belts transport items seamlessly from storage areas to packing stations, reducing the time and effort required for manual handling. This not only accelerates the order fulfilment process but also minimises the likelihood of errors in product selection.

Handling Diverse Products with Versatility

Distribution centres often deal with a diverse range of products, varying in size, shape, and weight. Conveyor systems, with their modular designs and customisable configurations, offer unparalleled versatility.

Whether it’s handling small packages in an e-commerce warehouse or managing bulky items in a traditional distribution centre, conveyor systems can be tailored to meet specific requirements. This adaptability ensures that the system can efficiently accommodate the unique characteristics of each product, optimising the overall workflow.

Maximising Space Utilisation

In the fast-paced world of distribution, real estate within a facility is a precious commodity. Conveyor systems contribute to maximising space utilisation by facilitating vertical storage and retrieval systems.

Through the integration of inclined or vertical conveyors, distribution centres can make the most of their available space, allowing for higher storage capacities and increased inventory turnover. This not only supports a higher volume of goods but also reduces the need for expansive floor space, contributing to cost-effective operations.

Enhancing Sorting and Routing Efficiency

Efficient sorting and routing are critical components of distribution centre operations. Conveyor systems, equipped with automated sorting technologies, can quickly and accurately categorise products based on various parameters such as destination, priority, or order type.

This automated sorting not only reduces the dependence on manual labour but also minimises the risk of errors associated with human intervention. The result is a well-organised and streamlined process, ensuring that each product reaches its designated location within the distribution centre with precision and speed.

Embracing Technology for Smarter Operations

In the era where connectivity and data-driven insights are shaping industries, conveyor systems are not lagging behind. Smart conveyor systems integrated with sensors, technology, and data analytics enable real-time monitoring of the entire distribution process.

This not only facilitates proactive maintenance, reducing downtime, but also provides valuable insights into the performance of the distribution centre. Businesses can leverage this data to optimise workflows, identify bottlenecks, and make informed decisions to enhance overall efficiency.

Promoting Workplace Safety

Beyond the obvious efficiency gains, conveyor systems contribute significantly to maintaining a safe working environment within distribution centres. By automating the movement of heavy and potentially hazardous items, these systems reduce the risk of injuries associated with manual handling.

Additionally, conveyor systems can be equipped with safety features such as emergency stop buttons, automated sensors, and comprehensive training protocols to ensure a secure working environment for all employees.

Contact Us Today

Looking to find out more information about conveyor systems for distribution centres? If so, it’s super easy to get in contact with our dedicated team. Simply call us today at 01908 592 354 or use our online contact form and we’ll get back to you promptly.

Drawing on our extensive background in warehouse automation, we instil confidence in our clients, empowering them to move forward. With our round-the-clock support, we stand ready to address any issues that may arise, ensuring a seamless operational experience without compromise

Your company’s success is paramount to us, and our dedicated team is committed to fostering its ongoing prosperity. Renowned for our profound industry knowledge, we bring a wealth of experience spanning diverse industry sectors.