Automated Material Handling Systems

Automated material handling systems are no longer just an option; they are essential in 2024 and beyond for enhancing safety, reducing costs, and boosting efficiency in your warehouse.

By Jake Powell

// 2 Jul 2024

These systems have transformed how businesses manage, move, and store materials. In this blog, we’ll explore what automated material handling systems are, their benefits, types, and real-world applications.

Key types of automated material handling systems available include:

- Automated Storage and Retrieval Systems (AS/RS)

- Automated Guided Vehicles (AGVs)

- Autonomous Mobile Robots (AMRs)

- Conveyor Systems

- Sortation Systems

If you require a site visit or would like to find out more about our automated material handling systems, please call us directly at 01908 592 354 or through our convenient online contact form.

What is an Automated Material Handling System?

Automated material handling systems refer to technology-driven solutions designed to manage the movement, storage, and control of materials throughout manufacturing, distribution, consumption, and disposal processes.

These systems integrate machinery, robotics, software, and control systems to automate tasks traditionally performed by manual labour. Warehouses often have one or multiple types of automated material handling systems including conveyor systems, AGV’s, and AMR’s.

Let’s get into the types of automated handling material systems available…

Automated Storage and Retrieval Systems (AS/RS)

Diamond Phoenix offer various Automated Storage and Retrieval System (ASRS) solutions in the form of pallet and miniload stacker cranes from our partners Cassioli and other Vertical storage systems.

Key features and benefits:

- Automatic warehouse with stacker cranes for high storage capacity.

- Unique functions (some of which internationally patented)

- Vertical warehouse systems for intensive storage of pallet and unit loads

- Satellite warehouse systems for traditional shelving

Automated Guided Vehicles (AGVs)

These are mobile robots that follow predetermined paths to transport materials within a facility. AGVs are commonly used in warehouses and manufacturing plants to move goods efficiently.

Key features and benefits:

- Execution of operations

- Elimination of destination errors

- Efficient, fast & flexible

- Compatible with various pallet size

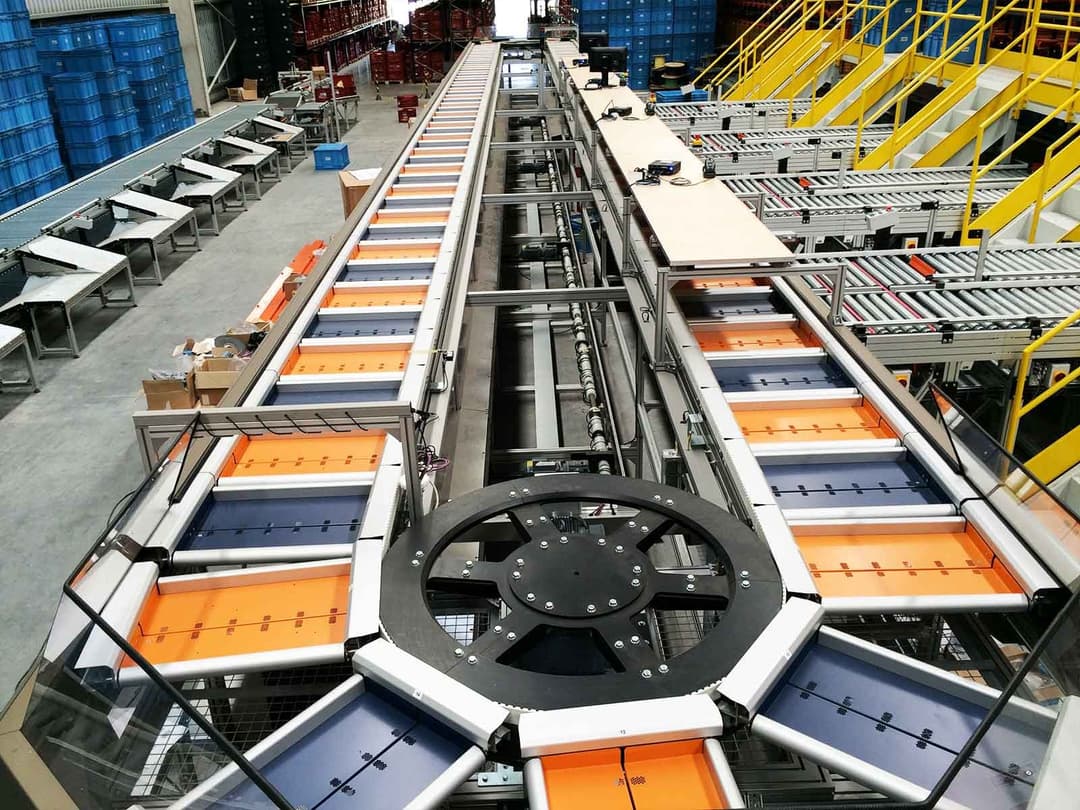

Conveyor Systems

Conveyors are used to move materials along a fixed path. These systems are highly efficient for transporting goods over short to medium distances and are commonly found in manufacturing and packaging industries.

Key features and benefits:

- Streamline warehouse operations

- Enhances scalability and operations

- Helps to reduce / minimise labour costs

- Up to six different types of conveyors

AMRs (Autonomous Mobile Robots)

AMRs are similar to AGVs but are classified as the next generation of AGV systems that are well-integrated with in-built software that can predict future moves and transportation processes.

Key features and benefits:

- Quick to install and modify

- Optimise and reduce staffing costs

- Can integrate with new or existing conveyor systems.

- Interactive with roller conveyors

Sortation Systems

These systems automatically sort products based on specific criteria, such as size, weight, or destination. Sortation systems are essential in logistics and e-commerce for efficient order fulfilment.

Key features and benefits:

- Used when high flow of cases, totes, or pieces needs to flow to different destinations

- Streamline and enhance packing operations

- Achieve and improve fast order processing

- Reduce overall labour costs

Real-World Applications

Warehousing and Distribution: Automated material handling systems are frequently used for warehousing and distribution to predominantly automate the storage, retrieval, and movement of goods. As a result of the selected automated material handling systems and therefore the faster order processing, this reduces the need for larger warehousing spaces.

Manufacturing: Within the manufacturing sector, automated material handling systems, such as conveyor systems and AGV’s, are used to transport raw materials to production lines and move finished products to storage or shipping areas. This automation minimises production downtime and enhances workflow efficiency.

E-commerce: Over the past decade or so, we have seen a huge demand in E-commerce warehouses using automated material handling systems for efficient order fulfilment. With the use of these systems, E-commerce operations have the ability to handle higher volumes or orders quickly and accurately, improving customer satisfaction.

Food and Beverage: The food industry uses automated material handling systems to handle ingredients, packaging materials, and finished products. Automation ensures hygienic handling and precise tracking of perishable goods.

The Future of Automated Material Handling Systems

In 2024 and beyond, the future of automated handling material systems is constantly evolving.

Due to the rise of AI (artificial intelligence), we expect major changes in the industry that we are always keeping up to date with to ensure we provide the most efficient and safe solutions for your warehouse capabilities.

Predictive maintenance, real-time data analytics, and enhanced connectivity will enable businesses to optimise their operations continuously.

Contact Diamond Phoenix Automation

Automated Material Handling Systems are revolutionising the way industries operate. By embracing automation, your operations can achieve higher efficiency, accuracy, and safety while reducing costs.

As we move towards an increasingly automated future, automated material handling systems will play a pivotal role in driving industrial innovation and growth.

If you’re looking to explore your options with automated material handling systems and receive expert advice on the best automation and robotic systems for your warehouse, please call us directly on 01908 592 354 or use our online contact form.