Automotive Conveyor Systems

Within the automotive industry, conveyor systems are essential for the movement of components and vehicles with precision and efficiency.

By Jake Powell

// 26 Mar 2024

However, not all conveyor systems are created equal, and choosing the right type can make all the difference in streamlining production processes.

In this blog, we’ll take a closer look at the different types of conveyor systems that are most suitable for the automotive industry including:

- Belt conveyors

- Chain conveyors

- Roller conveyors

- Overhead conveyors

- AGV’s (automated guided vehicles)

If you require a site visit or would like to find out more about our bespoke automotive conveyor solutions, please do not hesitate to reach out to us directly at 01908 592 354 or through our convenient online contact form.

Let’s get into the 5 key types of automotive conveyor systems (including AGV’s)…

Belt Conveyors

Belt conveyors are perhaps the most common type of conveyor system used in automotive manufacturing. These systems feature a continuous loop of material, typically made of rubber or PVC, that moves along a series of rollers or pulleys.

Moreover, they are versatile and can transport a wide range of components, from small parts to fully assembled vehicles, making them ideal for various stages of the assembly process.

Belt conveyors for automotive are exceptional for:

- Transporting components

- Assembly line integration

- Just-In-Time manufacturing

- Quality control

Chain Conveyors

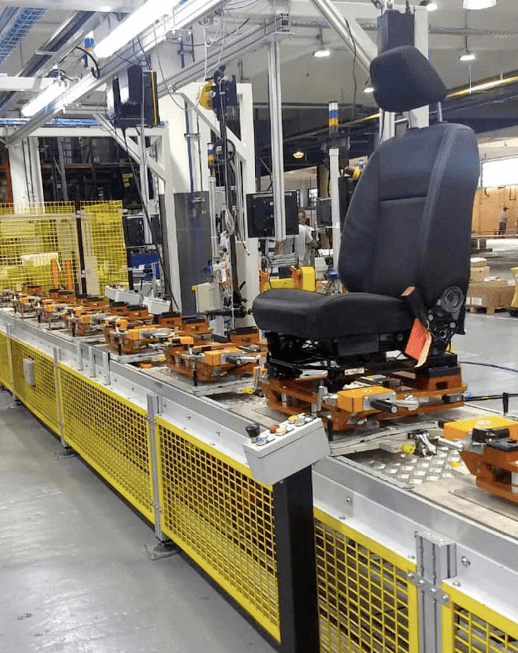

Chain conveyors are another popular choice for automotive manufacturing, especially in heavy-duty applications such as carrying large and heavy components like engine blocks or chassis frames.

These systems utilise chains or belts with attachments to move materials along a predetermined path. Furthermore, chain conveyors are known for their durability and reliability, making them well-suited for handling heavy loads in demanding industrial environments.

Chain conveyors for automotive are suitable for:

- Heavy-duty material handling

- Precision and control

- Integration with automation

- Quality control

Roller Conveyors

Roller conveyors consist of a series of rollers mounted on a frame, allowing materials to be transported by gravity or powered mechanisms.

In automotive manufacturing, roller conveyors are often used for tasks such as pallet handling, accumulation, and sorting.

These systems are efficient, low-maintenance, and ideal for moving components along straight or curved paths within the production facility.

Roller conveyors for automotive are suitable for:

- Accumulation and sorting

- Pallet handling

- Conveyor accumulation zones

- Quality control

Overhead Conveyors

Overhead conveyors offer a unique solution for transporting materials above the production floor, freeing up valuable space and allowing for greater flexibility in layout design.

In automotive manufacturing, overhead conveyors are commonly used for tasks such as paint finishing, where vehicles or components are suspended from the conveyor system as they move through the painting process.

Overhead conveyors are efficient, space-saving, and well-suited for applications that require continuous or intermittent movement of materials.

Overhead conveyors for automotive are suitable for:

- Space optimisation

- Continuous flow production

- Paint finishing applications

- Quality control

Automated Guided Vehicles (AGVs)

While not traditional conveyor systems in the traditional sense, Automated Guided Vehicles(AGVs) are becoming increasingly prevalent in automotive manufacturing for their ability to transport materials and components autonomously.

These self-guided vehicles navigate predetermined paths using sensors, lasers, or magnetic guidance systems.

AGVs offer flexibility and scalability, allowing manufacturers to adapt their production processes quickly to changing demands or layouts.

AGVs for automotive are suitable for:

- Integration with manufacturing systems

- Just-In-Time manufacturing

- Material transport

- Quality control

Automotive Conveyor Systems

In the dynamic world of automotive manufacturing, choosing the right conveyor system is essential for optimising efficiency, productivity, and safety.

Whether it’s belt conveyors for transporting small parts, chain conveyors for heavy-duty applications, or overhead conveyors for paint finishing, each type offers unique advantages tailored to specific manufacturing requirements.

By understanding the different types of conveyor systems available and their respective benefits, automotive manufacturers can design and implement assembly lines that meet the demands of today’s fast-paced industry.

Contact Diamond Phoenix

Diamond Phoenix Automation hopes that this blog has provided valuable insights into the different types of automotive conveyor systems to consider for manufacturing and production processes.

As experts in this field, we are equipped with a range of successful services to assist you. Should you require further assistance, please do not hesitate to reach out to us directly at 01908 592 354 or through our convenient online contact form.