Is Automation Right For Your Business?

Is Automation Right for Your Business?

By Diamond Phoenix

// 26 Nov 2025

Automation is often seen as the key to improving efficiency, reducing costs, and staying competitive. However, it isn’t a one-size-fits-all solution, and implementing the wrong system or investing without proper planning can lead to unnecessary costs and operational disruption.

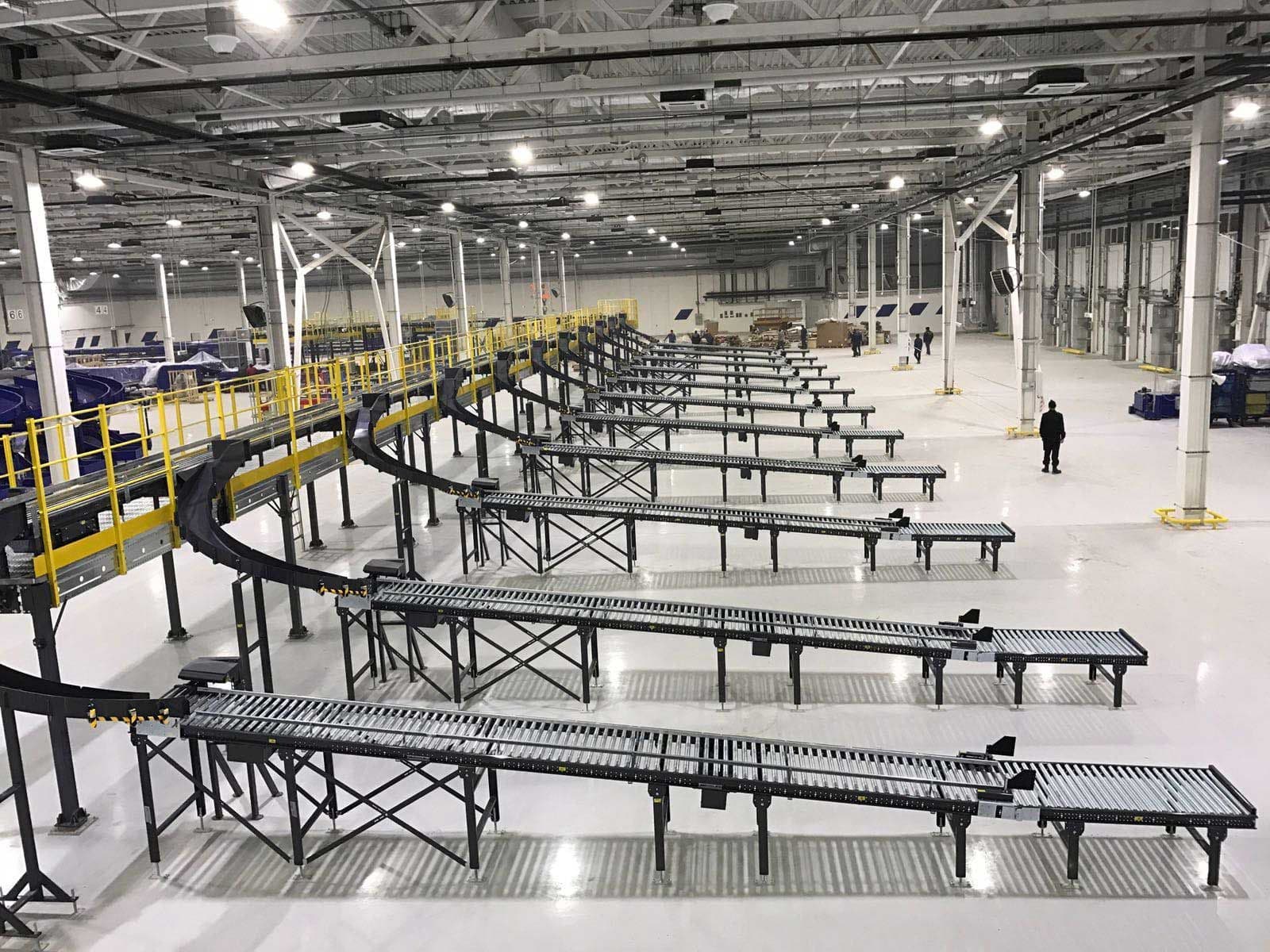

At Diamond Phoenix Automation, we supply and install a wide range of automated systems for warehouses, distribution centres, manufacturing plants, and many other industries across the UK.

Our range of solutions includes telescopic boom conveyors, bespoke conveyor systems, pallet conveyor systems, automated guided vehicles, autonomous mobile robots, and more.

Before making any investment in automation, it’s crucial for business owners and operations managers to ask the right questions.

Understanding your goals, operational requirements, and long-term objectives ensures that automation delivers real value and improves your operations rather than creating new problems.

Key Questions to Consider Before Investing in Automation:

- What Are Your Operational Goals?

- What Volume and Scale Do You Need?

- What Type of Automation Fits Your Needs?

- What Is Your Budget?

- How Will Automation Integrate Seamlessly?

- What Are the Maintenance Requirements?

- What Is the Expected ROI and Payback Period?

Call us today at 01908 592354 or use our contact form to arrange a free consultation.

Let’s explore these key questions in further detail…

1. What Are Your Operational Goals?

The first step before deciding whether, and what type of, automation to invest in is to define your operational goals. And secondly: What challenges am I trying to solve? It's paramount to determine your key objectives which may include reducing labour costs, making your operations safer, improving accuracy, increasing throughput, or a combination of the above.

At Diamond Phoenix Automation, we help you to answer these all important questions, and tailor automation solutions to your specific business goals and objectives. It's important to look at the key pain points of your current operations and identify key automation solutions.

For example, if order picking is your bottleneck, a pick-to-light or automated sortation system may be required.

2. What Volume and Scale Do You Need?

Every business and operation requires different levels of automation and this is often largely dependent on your scalability aspirations and the volume of goods and products you're looking to ship out daily, monthly, and annually.

For large-scale operations, fully automated systems may be absolutely necessary and financially make complete sense. However, for small businesses or facilities with moderate throughput, semi-automated solutions for specific tasks may provide the best balance between efficiency and cost.

Our automation experts at Diamond Phoenix Automation can help you identify the quantity and type of automation you need.

3. What Type of Automation Fits Your Needs?

The third key question is: What type of automation fits your needs? Automation is an umbrella term and covers various different types of automation solutions.

What's ideal for your business and operations will largely depend on the questions already covered.

Common solutions include:

- Conveyor systems – ideal for moving products and goods efficiently.

- Telescopic conveyors – for loading and unloading vehicles quickly.

- Pallet systems – efficient for heavy-duty movement and storage.

- Sortation systems – help organize products and improve order accuracy.

- Automated picking solutions – reduce human error & speed up fulfilment.

Choosing the right solution requires a clear understanding of your products, workflow, and space constraints.

Diamond Phoenix Automation is an experienced automation provider that can help determine which systems will deliver the best results.

4. What Is Your Budget?

While automation can deliver substantial long-term savings, it often requires a significant initial investment. That's why it's incredibly important to have an allocated budget towards automation solutions.

We highly recommend considering both upfront costs and long-term expenses and to include these in your budget, including:

- Professional Installation and setup

- Integration with existing systems

- Ongoing maintenance and servicing

- Comprehensive staff training

Taking the time to conduct a cost analysis is also recommended by our expert team. Here, you can calculate the cost of ownership and initial installation, and compare to the benefits it will bring to your operations, such as increased profit margins, reduced labour expenses, fewer errors, and further savings.

5. How Will Automation Integrate With Existing Operations?

It's important to consider your existing operations, and think strategically about how automation will integrate. With newly installed and integrated automation, it's paramount to hit the ground running and to ensure a seamless approach alongside current workflows, infrastructure, and software. As a result of seamless integration, you reduce bottlenecks and avoid disrupting operations.

Consider factors like floor space, workflow design, and compatibility with existing machinery. Planning for smooth installation and commissioning helps avoid operational downtime and ensures your team can start reaping the benefits of automation quickly.

6. What Are the Maintenance Requirements?

Another key question to consider is: What are the maintenance and support requirements? Regular maintenance and reliable support are imperative to keep systems running smoothly all-year-round, and this should be carefully thought out. You can ask Diamond Phoenix Automation about our maintenance schedules, available support services, and response times for urgent issues.

Moreover, to put your mind at ease with this important question, we also cover regular servicing across the entirety of the UK, ensuring that any unexpected problems can be addressed quickly, minimising downtime and protecting your investment.

7. What Is the Expected ROI?

Just like any costly upfront investment, an expected ROI should be calculated over a specific time period based on its potential return.

For example, for most businesses, our Convey Xpress Telescopic Boom Conveyors, achieve return on investment within 12–18 months, thanks to savings in labour, time, and injury-related costs.

Key factors affecting ROI include:

- Labour cost reductions

- Increased throughput and productivity

- Improved order accuracy and reduced errors

- Reduced workplace injuries and associated costs

Contact Diamond Phoenix Automation

Seeking high-quality and proven automated solutions, such as telescopic boom conveyors and bespoke conveyor systems?

At Diamond Phoenix, we specialise in helping businesses evaluate, design, and implement automation solutions tailored to their unique needs.

Our experienced team can guide you through every step and determine suitability of automation for your operations. From consultation and installation to ongoing servicing and support, we cover every type of support you require.

Call us today on 01908 592354 to arrange your free consultation.

Alternatively, send your enquiry via our online contact form.